Kukje Gallery

ITA | ENG

© Iwan Baan

Concept

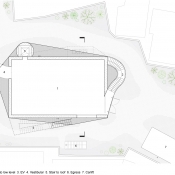

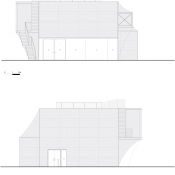

The architectural proposal resolves a perceived disjunction between the dynamism and boldness of Kukje Gallery’s organization and artist roster, and the fragile historic fabric saturated by materials and details that surrounds the site. Studies led to a soft and ambiguous building that gently nestles itself into the site.

© SO – IL

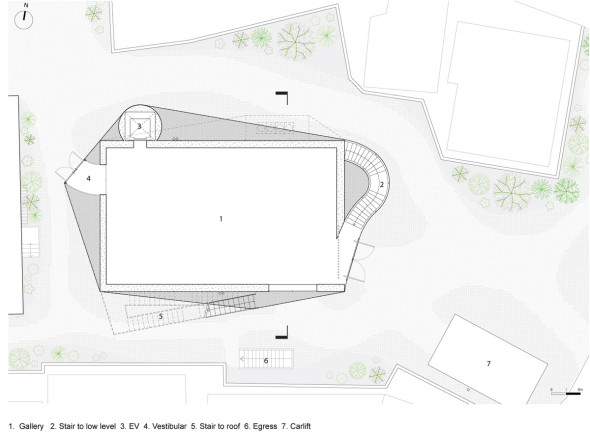

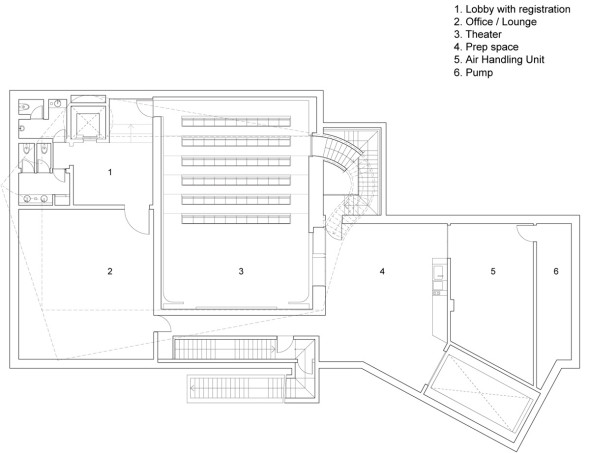

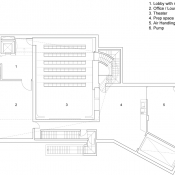

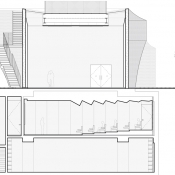

Circulation—entries, vestibules, elevators and stairs—has been pushed out of the orthogonal gallery space to maximize its height and maintain a clear interior volume.

© SO – IL

© SO – IL

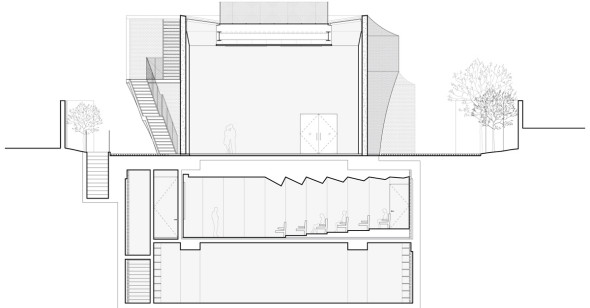

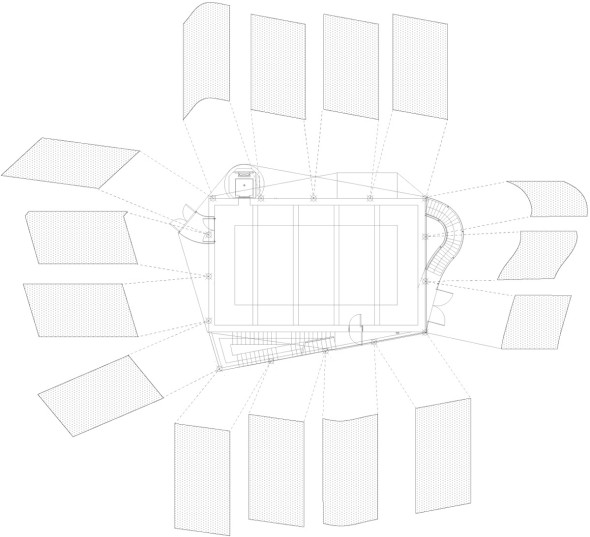

Considering the diagrammatic box geometry too rigid within the historic fabric, SO – IL enveloped the building in a mesh veil, creating a nebulous exterior that changes appearance as visitors move through the site. A custom stainless steel mesh produces a layer of diffusion around the structure, through a combination of reflections, openness, and moiré patterns produced through the interplay of its shadows.

© SO – IL

The mesh, made out of 510.000 individually welded rings, is strong yet pliable as it wraps around the building’s irregular geometries. The result is an abstract ‘fuzzy’ object that accommodates a multiplicity of readings.

© SO – IL

Program

The building contains a 16 x 9 x 6m gallery space, a 60 seat auditorium, project spaces, support and administrative functions for the gallery complex. The ground floor gallery is a single-story, column-free space optimized for large installations, performances and events. To light the art and keep a palpable relationship to the outside, daylight enters through a perimeter skylight. The skylight can be shaded or completely darkened, to create a black-box condition, which allows for light sensitive works or video.

© Iwan Baan

The first of two lower levels holds a 60 seat dark stained wood-clad auditorium, administrative areas, catering spaces, restrooms and mechanical spaces. The second basement holds storage and support spaces.

© Iwan Baan

Mesh

Through extensive research, conducted together with Front Inc – a façade engineering firm– we created this one-off façade. The mesh was produced with local craftsmen in Anping, China, under tight supervision and quality control by Front / Via LLC and SO – IL.

© Iwan Baan

The technical innovations include Front’s development of a highly flexible perimeter attachment system that allows the mesh to form find for itself and develop an equilibrated pre-stress, eliminating wrinkling and stress concentrations.

© Iwan Baan

Equally significant was the development of a computational process for modelling the way the mesh would drape over the building. This allowed Front to predict the number of needed rings at each location and create precise finite element engineering models.

© Iwan Baan

From a material and façade engineering standpoint this is a ground-breaking project which will enable an unprecedented exploration of ‘atmospheric’ surfaces.

Gallery

Credits

- project > SO – IL

- project team > Florian Idenburg (partner), Jing Liu (partner), Iannis Kandyliaris, Cheon-Kang Park, Sooran Kim

- location > Seoul (Corea del Sud)

- program > art gallery

- dimension > 1260 mq

- chronology > 2012

- photo credits > Iwan Baan

Pagine: 1 2

Questo sito usa Akismet per ridurre lo spam. Scopri come i tuoi dati vengono elaborati.

Lascia un commento