Factory Futures

ITA | ENG

© Architectural Association

From the 16th to the 27th of July 2012, the Architectural Association and the Adriano Olivetti Foundation – in partnership with the City of Ivrea and Gehry Technologies Europe – have boldly introduced the Factory Futures project to a global and local audience through a twelve days experimental design programme held entirely at the former Olivetti complex in Ivrea (Italy) as part of the worldwide AA Visiting School programme and the current Adriano Olivetti Foundation’s cultural initiatives on the territory.

© Architectural Association

This year’s programme culminated in a public exhibition at the Salone dei 2000 – Olivetti ICO Factory – featuring the work of the students in presence of international guest critics, journalists and members of the local administration.

© Architectural Association

Twelve students coming from four different continents immerged themselves in the Olivettian culture and architectures with the objective of building a large scale architectural prototype responding to the emerging conditions of production of the site. A series of lectures and field trips critically introduced the students to the Olivettian social and architectural values, the reality of local call centres and the most recent studies focusing on the relation between modern subjectivity and the working environments of late capitalism.

© Architectural Association

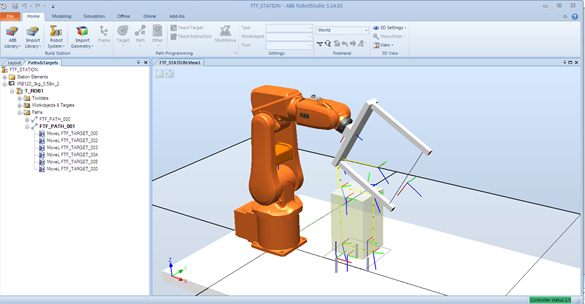

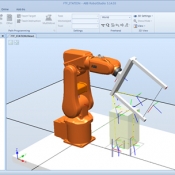

In pursuing a very Olivettian intersection between social theory and advanced technological applications, students were introduced to the highly contemporary topic of integrated design. In depth insights on digital technologies in the building industry and real architectural projects have been provided alongside intensive and hands-on workshops on associative and parametric modelling (Digital Project) as well as machine control and simulation (RobotStudio) for Robotic Fabrication.

© Architectural Association

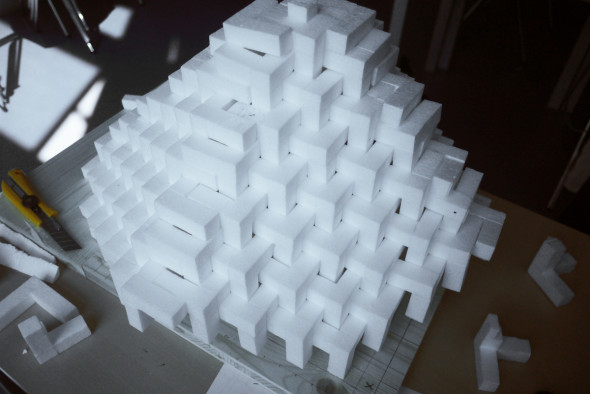

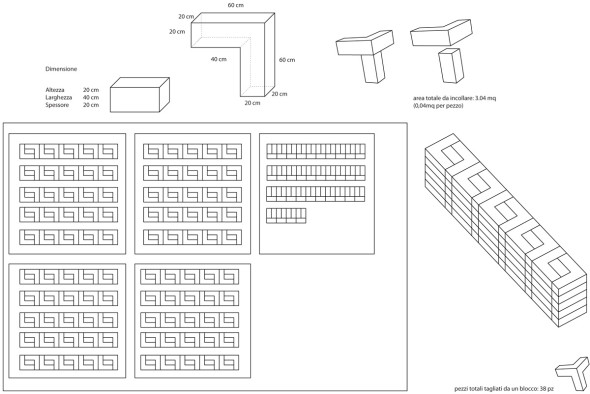

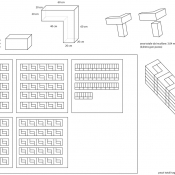

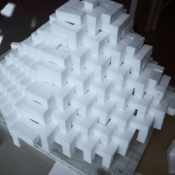

Students focused on the design of a production cycle as a driver for the generation of architectural form: a given amount of twelve cubic meters of polystyrene was to be cut through the machines of a local factory – some large scale hot wire cutters – and assembled at the former Olivetti Factories on a strict timeline. Manufacturing possibilities, assembly logics, and production timelines have been the key ingredients of our architectural speculations.

© Architectural Association

In the first week, a number of grid and component based systems were explored starting from an abstraction of the materials found during the Olivettian field trips. In the second phase, students focused on the systematization of the final prototype as a result of the discussions, the experiments and the collective decisions of week 1.

© Architectural Association

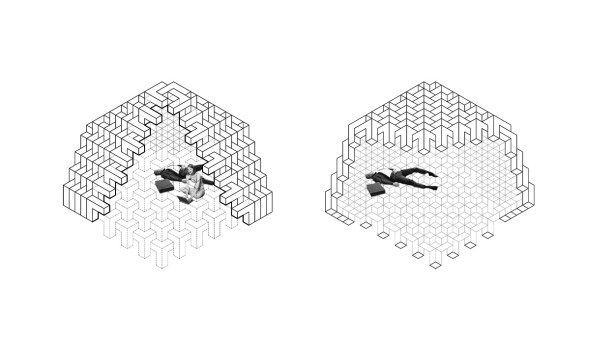

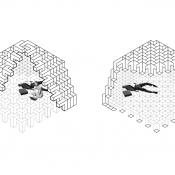

As we explored a cheap, elemental and collective building system derived from the systemic exploration of the production and assembly logics of one component, this methodology brought us closer to an Eskimo community and their igloos rather than a contemporary design practice. Instead of proposing a purely functional response to a problem, the final prototype has been conceived as an open – yet hyper specific – system. Through drawings and collages, we imagined it as a micro-environment able to colonize the typical open plan of the factory and where – as a result of the ubiquitous presence of technology – both work and life activities could find place on carpets under this self-contained and individualized space.

© Architectural Association

The production and assembly of the final prototype took a total of three days. Components were mass produced in the factory by optimizing manufacturing cutting times and the available quantities of material by adapting the size of the components to the given dimension of the original polystyrene blocks. No material has been wasted out of the 156 components produced and because of the self-supporting qualities of the structure a minimal amount of gluing was required.

Gallery

Credits

- workshop > Factory Futures

- tutors > Tommaso Franzolini, Pierre Cutellic, Rupert Malczeck, Chloe Genevaux, Guillaume Bounoure, Benedetta Gargiulo

- guests > Patrizia Bonifazio, Francisco Gonzales, Nuria Lombarderos

- students > Alessandra di Leo, Aleksandar Celovic, Carlo Alberto Gasperini, Solana Costa del Rio, Stefano Pavone, Ruben Carboni, Mirka Skudar, Nikolina Pavlovic, Antonio Moll, Sara Saghafi, Denim Pascucci, Bonaventura Visconti, Clemens Jenny

- organization > Architectural Association

- partners > Fondazione Adriano Olivetti, Gehry Technologies Europe, Come di Ivrea, Archiwaste

- location > Ivrea (Italy)

- anno > 2012

Related Posts

Pagine: 1 2

Questo sito usa Akismet per ridurre lo spam. Scopri come i tuoi dati vengono elaborati.

Lascia un commento